It is the 1st World, Modular HDPE Plant.

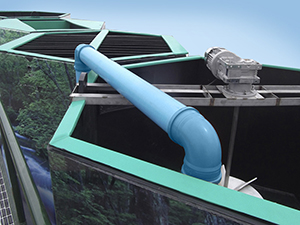

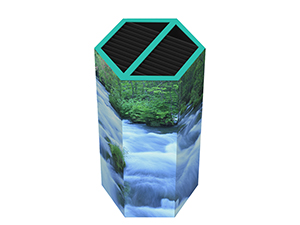

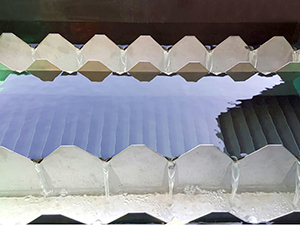

This new modular plant for the purification of fresh water, surface or underground, is easily transportable, built in HDPE (which provides a solution against oxidizing agents), with the almost zero execution of civil works, designed so that individual processes are perform in hexagonal reactors (which optimize these processes), which leads to a minimization of the occupied spaces, and the obtaining of large flows of drinking water; compared to traditional plants, so that installation costs are drastically reduced as well as maintenance costs, where a single operator without major difficulty can become responsible for the management and maintenance of the plant.

Allowing in a future to expand without limits, the flows of purification, without having to interrupt the Services of distribution to the population.

The saving of investment and operating costs are the result of the conception and design of individual modules of Hexagonal Prisms, built in high density polyethylene (HDPE), equal in shape and size that allow the configuration of an original open mosaic, a its modification with the incorporation of new modules. With a minimum investment, an “upgrade” is achieved that will also make possible a reduction in the dosage of chemical products and will simultaneously cause higher sedimentation loads and higher filtration rates, resulting in an improvement in the quality of the water produced , an increase in treatment capacity and significant savings in operating costs, because no more human resources should be required for the same functions.

We start from the imperative need for the presence of water for life to exist. Water is the main clue that scientists who seek life today follow...